Light Weight Aluminum Castings Explained: Key Advantages and Services for Your Production Requirements

Light weight aluminum castings play a considerable duty in modern production. Their resilient and light-weight nature makes them ideal for various applications. Industries such as automobile and aerospace gain from their convenience. Recognizing the advantages and the manufacturing procedure of aluminum castings is important. In addition, picking the right solution provider can impact top quality and effectiveness. What elements should be thought about when selecting a light weight aluminum spreading solution? Exploring these facets discloses crucial insights.

Benefits of Light Weight Aluminum Castings

Aluminum castings supply various benefits that make them a favored choice in different markets. Among the primary benefits is their light-weight nature, which significantly reduces shipping and dealing with expenses. Additionally, light weight aluminum exhibits outstanding rust resistance, making sure durability and lowered maintenance for items made from this material. The adaptability of aluminum enables complex designs and complex shapes, offering suppliers with greater adaptability in production.

In addition, aluminum castings possess excellent thermal and electrical conductivity, making them suitable for a selection of applications needing warm dissipation or electrical elements. The product also has a high strength-to-weight proportion, enabling the production of sturdy yet lightweight elements. Furthermore, aluminum can be reused without losing its buildings, promoting sustainability in producing procedures. In general, these benefits make aluminum castings a trustworthy and reliable alternative for producers seeking high quality and performance in their products.

Applications of Aluminum Castings in Numerous Industries

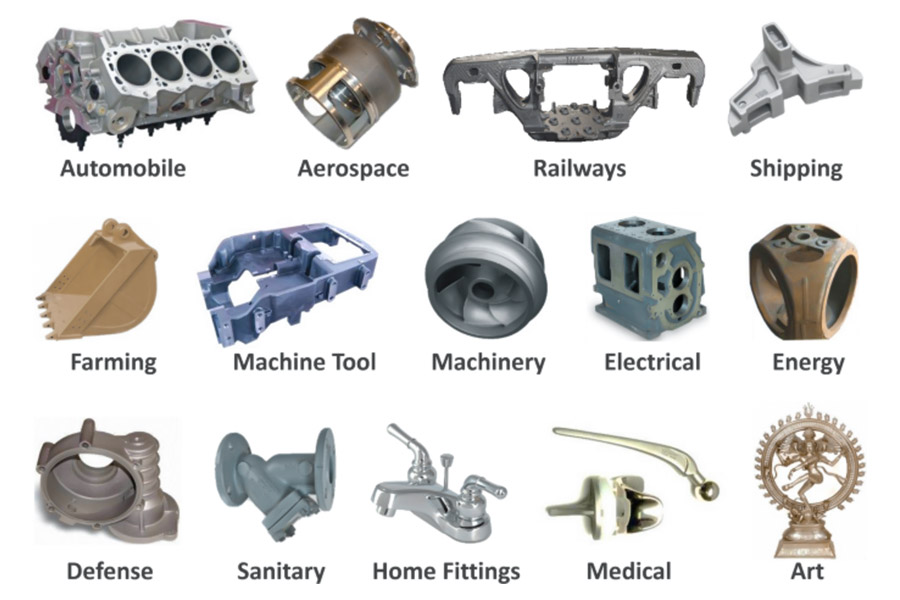

The benefits of aluminum castings make them extremely searched for throughout numerous sectors, including vehicle, aerospace, and durable goods. In the automotive market, they are used for engine blocks, transmission situations, and wheels because of their light-weight nature, which boosts gas performance. Aerospace applications benefit from aluminum castings in structural components and housings, giving toughness while minimizing weight, vital for trip performance.

In customer goods, aluminum castings are used in products such as kitchenware and electronic enclosures, offering durability and visual charm (Wisconsin Aluminum Foundry). Additionally, the electrical industry utilizes light weight aluminum castings for warmth sinks and real estates, guaranteeing reliable thermal monitoring. The convenience of aluminum enables complicated geometries and intricate styles, better increasing its applications. In general, the varied energy of aluminum spreadings highlights their importance in modern-day production, adding to development and efficiency throughout these crucial markets

The Production Refine of Aluminum Castings

Casting light weight aluminum entails several critical actions that transform raw steel right into accurate parts. The process starts with the melting of aluminum scrap or ingots in a heater, getting to temperature levels around 1,200 ° F. Once molten, the aluminum is poured right into a mold and mildew, which can be made from sand, metal, or ceramic, relying on the wanted specs.

After putting, the metal solidifies and cools down, creating the form of the mold (Wisconsin Aluminum Foundry). The following step includes removing the casting from the mold, which might call for added techniques to ensure a smooth surface coating

Subsequently, any excess material or flaws can be machined or ground off to attain the final measurements. Quality assessments are then conducted to verify that the spreading satisfies needed standards. This meticulous process enables makers to create elements that are light-weight, resilient, and ideal for a wide variety of applications.

Selecting the Right Aluminum Casting Service

When picking an aluminum casting service, it is necessary to ponder numerous aspects that can considerably impact visit our website the high quality and performance of the final product. The solution supplier's experience and expertise in light weight aluminum spreading play a crucial duty in making certain high-grade outcomes. Companies ought to examine the supplier's profile and previous projects to assess their abilities.

Furthermore, evaluating the technology and equipment made use of by the casting solution is very important, as modern machinery can enhance precision and reduce lead times. An additional crucial factor is the capacity to supply tailored options customized to certain job demands, which can considerably boost product performance.

Furthermore, interaction and customer assistance need to not be ignored; a collective companion can facilitate smoother project implementation. Lastly, thinking about cost-effectiveness without jeopardizing top quality is crucial for making a notified decision. By meticulously considering these facets, producers can select a spreading service that finest satisfies their demands.

Future Fads in Aluminum Casting Modern Technology

As producers progressively focus on high quality and performance, advancements in aluminum spreading technology are set to transform the industry. Arising fads consist of the adoption of automation and robotics, which boost accuracy see this site and minimize human error in casting processes. Additionally, the combination of synthetic intelligence and artificial intelligence is expected to optimize manufacturing timetables and improve quality assurance.

Sustainability stays a main emphasis, with advancements in recycling strategies enabling extra efficient reuse of light weight aluminum scrap, thereby lowering waste and energy consumption. Advanced simulation software program is additionally gaining grip, allowing designers to version and forecast casting performance prior to real manufacturing, reducing pricey errors.

The growth of new alloys and progressed spreading methods, such as 3D printing, will certainly broaden the opportunities for light-weight yet durable parts. Together, these patterns suggest a vibrant future for light weight aluminum spreading, driven by technical developments that focus on sustainability, item, and efficiency high quality.

Frequently Asked Questions

Just How Do Aluminum Castings Contrast to Various Other Materials?

What Are the Weight Limitations for Aluminum Castings?

Weight limitations for light weight aluminum castings usually rely on the layout and application, yet they normally support load capacities ranging from a few ounces to several bunches. Specific restrictions arise from variables like wall surface density and architectural honesty.

Can Light Weight Aluminum Castings Be Repaired After Production?

Light weight aluminum castings can be fixed after manufacturing, utilizing strategies such as welding or epoxy bonding. click to read more The expediency of repair work relies on the extent of damages and the specific homes of the aluminum alloy used.

What Finishes Are Available for Light Weight Aluminum Castings?

Numerous finishes are readily available for light weight aluminum spreadings, including anodizing, powder paint, coating, and sprucing up. These coatings improve appearance, provide deterioration resistance, and boost surface longevity, catering to varied aesthetic and functional requirements in making applications.

How Do Environmental Laws Affect Light Weight Aluminum Spreading Processes?

Environmental policies significantly affect light weight aluminum casting processes by mandating stricter discharges controls, encouraging reusing methods, and promoting sustainable products. These policies urge suppliers to embrace cleaner innovations and lower their environmental footprint in manufacturing tasks.